ELECTRIC OIL FREE SCREW AIR COMPRESSORS

If your application requires the utmost air quality, then oil-free is where you need to look.

ELGi’s oil free screw air compressors are one among the major outcomes of ELGi’s expertise in manufacturing and marketing of air compressors worldwide for the past 50 years. These compressors are backed by emerging technology that conserves natural resources and environment from pollution.

Applications

- Textiles

- Electronics

- Air Separation

- Food and Beverages

Uncompromising Air Purity for Critical Applications

ELGi's oil-free air compressors are designed for industries where even trace amounts of oil can be detrimental to processes and products. These compressors eliminate the risk of oil contamination, ensuring the highest air quality for applications such as:

Textiles:

Oil-free air is crucial in textile manufacturing to prevent contamination of delicate fibers, ensuring consistent dye uptake and preventing imperfections in the final product. This results in higher quality textiles and reduces waste due to defects.

Electronics:

In electronics manufacturing, even microscopic oil particles can damage sensitive components and compromise product reliability. ELGi's oil-free air compressors provide the clean, dry air necessary for the intricate processes involved in producing semiconductors, circuit boards, and other electronic devices.

Air Separation:

The production of gases like oxygen, nitrogen, and argon requires extremely pure air as a feedstock. Oil-free compressors ensure the efficiency and reliability of air separation units, preventing contamination of the final gas products.

Food and Beverages:

In the food and beverage industry, oil contamination can have serious consequences, affecting product taste, quality, and safety. ELGi's oil-free air compressors help maintain the stringent hygiene standards required in food and beverage processing, protecting consumers and preserving brand reputation.

Pharmaceuticals:

The pharmaceutical industry demands the highest levels of air purity to prevent contamination of drug products and ensure patient safety. ELGi's oil-free compressors provide the clean, sterile air needed for critical pharmaceutical processes, from drug synthesis to sterile packaging.

Healthcare:

Clean, oil-free air is essential in hospitals and medical facilities for applications such as supplying air to ventilat ors, powering surgical tools, and maintaining sterile environments. ELGi oil-free air compressors contribute to patient safety and the overall quality of healthcare.

Chemical Processing:

Many chemical reactions and processes are highly sensitive to contamination, including even trace amounts of oil. ELGi's oil-free compressors ensure the purity of air used in chemical processing, preventing unwanted reactions and ensuring consistent product quality.

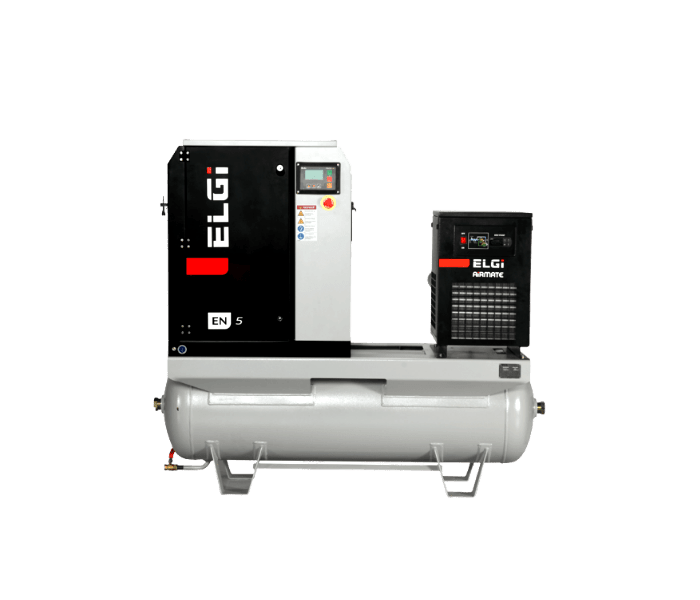

ROTARY SCREW AIR COMPRESSORS

Explore our range of oil-injected rotary screw air compressors for applications where oil-free air is not required. These compressors offer high performance and reliability for general industrial use.

View ProductsAIR DRYERS

Ensure dry, clean air for your compressed air system with our range of air dryers. We offer various dryer types to meet your specific needs, including refrigerated, desiccant, and membrane dryers.

View ProductsAIR FILTER

Protect your equipment and processes with our high-quality air filters. We offer a complete range of filters to remove contaminants such as dust, oil, and moisture from your compressed air.

View ProductsSERVICE

Maximize the lifespan and performance of your ELGi compressor with our comprehensive service and maintenance programs. Our factory-trained technicians provide expert support and ensure your equipment is running smoothly.

View ProductsPARTS

Get genuine ELGi parts and accessories to keep your compressor operating at its best. We offer a wide range of parts for all ELGi models.

View ProductsFREQUENTLY ASKED QUESTIONS

Class '0' oil-free air, as defined by ISO 8573-1, means that the compressed air is guaranteed to contain virtually no oil. This is crucial for applications where even trace amounts of oil can be harmful.

Maintenance intervals vary depending on the specific model and operating conditions. Refer to your compressor's technical manual for recommended maintenance schedules. We also offer service contracts to help you keep your compressor in top condition.

PTFE coating reduces friction, increases efficiency, and extends the life of the airend, leading to improved performance and long-term reliability.

The choice between air-cooled and water-cooled systems depends on factors like ambient temperature, available space, and water availability. Our experts can help you determine the best option for your needs.

Yes, ELGi compressors are designed with energy efficiency in mind, helping you reduce operating costs and your environmental footprint. Our high-efficiency designs maximize uptime while minimizing energy consumption.