When you choose Evergreen Compressed Air and Vacuum as your compressed air system partner, you’re choosing quality and efficiency. We offer a diverse selection of dependable, top-notch, energy-efficient, and easily manageable industrial air compressors for an array of industries. At Evergreen Compressed Air, we can assure you that we have an air compressor to fit your requirements and keep your mind at ease. We stock brands you trust from ELGi air compressors and compressed air dryers, Pattons Medical gas systems, and Champion reciprocating compressors.

Rotary Screw Air Compressors

ELGi’s rotary screw compressors come with options for both lubricated and oil-free systems. These air compressors are well-suited for industrial applications where size matters; offering high reliability, cost-effectiveness, and minimal maintenance.

View ProductsOil-free Screw Air Compressors

Oil-free air compressors are cutting-edge machines designed to deliver compressed air without the use of oil lubrication. This feature is crucial for industries requiring pristine air quality, such as food processing, pharmaceuticals, and electronics manufacturing, where even trace amounts of oil can compromise product integrity.

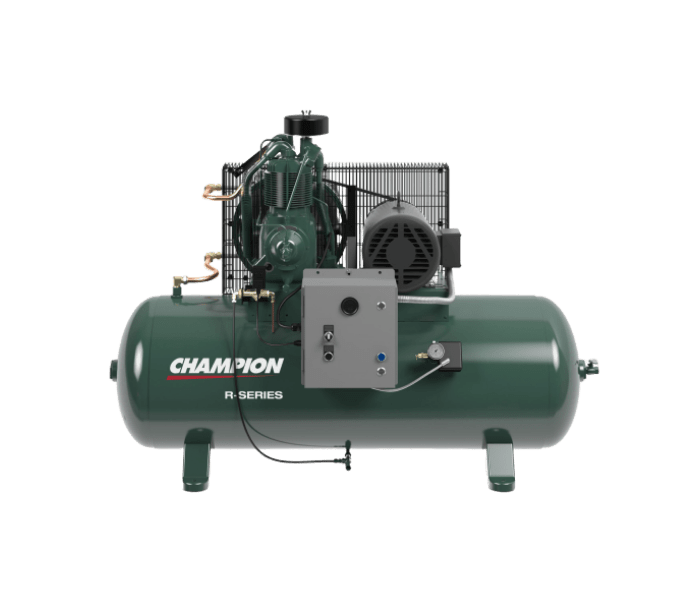

View ProductsReciprocating Air Compressors

Evergreen offers reciprocating air compressors, ideal for active workshops and facilities with intermittent compressed air needs, featuring a three-year warranty on pumps, tanks, and motors; these compressors provide secure, dependable, and high-performance solutions with minimal maintenance requirements.

View ProductsPortable Air Compressors

ELGi has 60+ years of experience in design, manufacturing, and distribution in the industrial, construction and agricultural sectors, characterised by their secure, dependable, and high-performance.

View ProductsMedical Air Compressors

Evergreen provides medical equipment from Pattons Medical, including medical scroll compressors, vacuum pumps, driers, and other medical gas equipment, playing a significant role in the healthcare sector. Pattons Medical has 15+ years of experience in serving the medical and laboratory market.

View ProductsHow to select the best air compressor for your needs

Evergreen Compressed Air and Vacuum offers compressed air solutions across a variety of industries including automotive, food and beverage, furniture, textiles, aerospace, pharmaceutical, medical, and general manufacturing. Selecting the right industrial air compressor is a strategic investment in your operations, ensuring productivity, efficiency, and cost-effectiveness in the long run.

Assess Your Needs

Before diving into the world of air compressors, evaluate your compressed air needs, taking into account factors such as air consumption rate, required pressure, and duty cycle (intermittent or continuous operation). Understand the type of applications you'll be using the compressor for – whether it's pneumatic tools, industrial processes, or medical equipment.

Consider Key Factors

Pay attention to these essential factors when choosing an industrial air compressor:

- Type of Compressor : Reciprocating, rotary screw, or centrifugal – each type has distinct advantages based on usage and efficiency.

- Flow Rate and Pressure : Ensure the compressor's output matches your needs in terms of cubic feet per minute (CFM) and pressure (psi).

- Energy Efficiency : Opt for features like variable speed drives (VSD) to match air output with demand, saving energy.

- Maintenance Requirements : Balance your team's capabilities with the maintenance needs of the compressor. Some models require more attention than others.

- Noise Levels : Consider your operational environment and choose a compressor that aligns with noise regulations.

Call in the Experts

At Evergreen Compressed Air and Vacuum, we know compressed air systems. We have a team of dedicated and trustworthy employees ready to answer any questions you have about purchasing an industrial air compressor and can guide you to make the best choice for your industry. We offer air compressor sales, repair, and maintenance to greater Seattle, Tacoma, Everett, and Olympia areas in Washington State. Contact us today for a quote!

FREQUENTLY ASKED QUESTIONS

Oil-lubricated compressors use oil for cooling and lubrication, offering better efficiency for heavy-duty applications. Oil-free compressors, on the other hand, are ideal for environments where air quality is crucial, like medical and food industries, as they prevent oil contamination.

Regular maintenance is key to ensuring your air compressor stays healthy. Check and change filters, monitor oil levels, drain condensate regularly, and keep the compressor clean. Follow manufacturer guidelines for maintenance schedules and keep a log to track servicing activities.

Variable Frequency Drives (VFD) are a popular energy-saving feature. They adjust the compressor's motor speed to match air demand, reducing energy consumption during periods of lower usage and improving overall efficiency.

Always wear appropriate safety gear, such as goggles and hearing protection. Prevent over-pressurization by using pressure regulators. Properly install and ground the compressor. Regularly inspect and maintain the unit, and never bypass safety devices or safety valves.